CAF-Elhuyar 2018: A circular solution against local waste that is swallowing the world

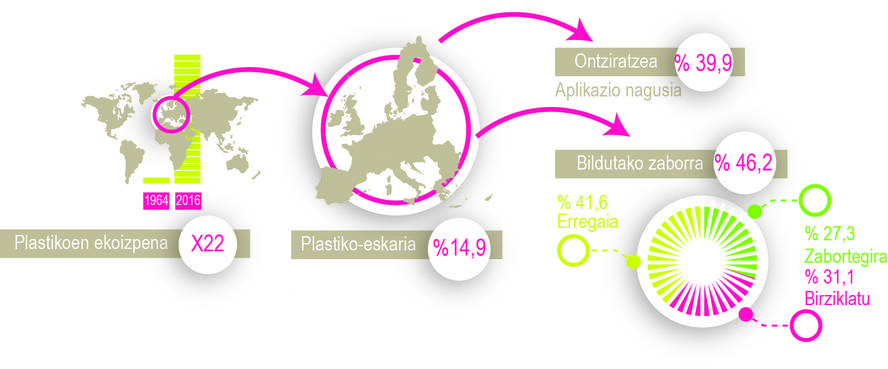

Cheap, easy to transform, sustainable, lightweight and versatile, global plastic production has increased considerably over the past 52 years. In 1964 15 million tons (MT) of plastics were generated, while in 2016 335 MT were generated, which is 22 times more. In Europe the demand for plastics was 49.9 Tm, being the main raw material for packaging applications. Only 42.6% of the waste generated from the plastic products produced was collected, of which 41.6% was used as fuel, 27.3% went to landfills and 31.1% was recycled (Figure 1).

According to data obtained, between 2006 and 2016 the amount of recycled plastic increased by 79%. This data raises the doubt that if more and more is recycled, why does the production of plastics continue to increase considerably year after year? The production of plastics is expected to double by 2036.

As mentioned, among the many applications plastic has, packaging is the main one. For humans, packaging has become a necessary and fundamental consumer issue for everyday life, since packaging has a number of functions such as maintaining, protecting, being practical, communicating and ensuring the quality and good health of food. The type of plastic is chosen according to its use. The plastics most commonly used in packaging are identified with the Möbius circle (Figure 2). In the center of the circle of Möbius we can see the numbers 1 to 7 indicating the type of plastic with which the product is made. The symbol does not indicate that the product is recyclable or made of recycled material. The same conceptual confusion occurs with a symbol of organization similar to the yin-yang formed by two arrows. The so-called green dot indicates that the producers of the product have made an economic contribution to recycle plastic somewhere in the world, but not that the product is recyclable or made of recycled materials.

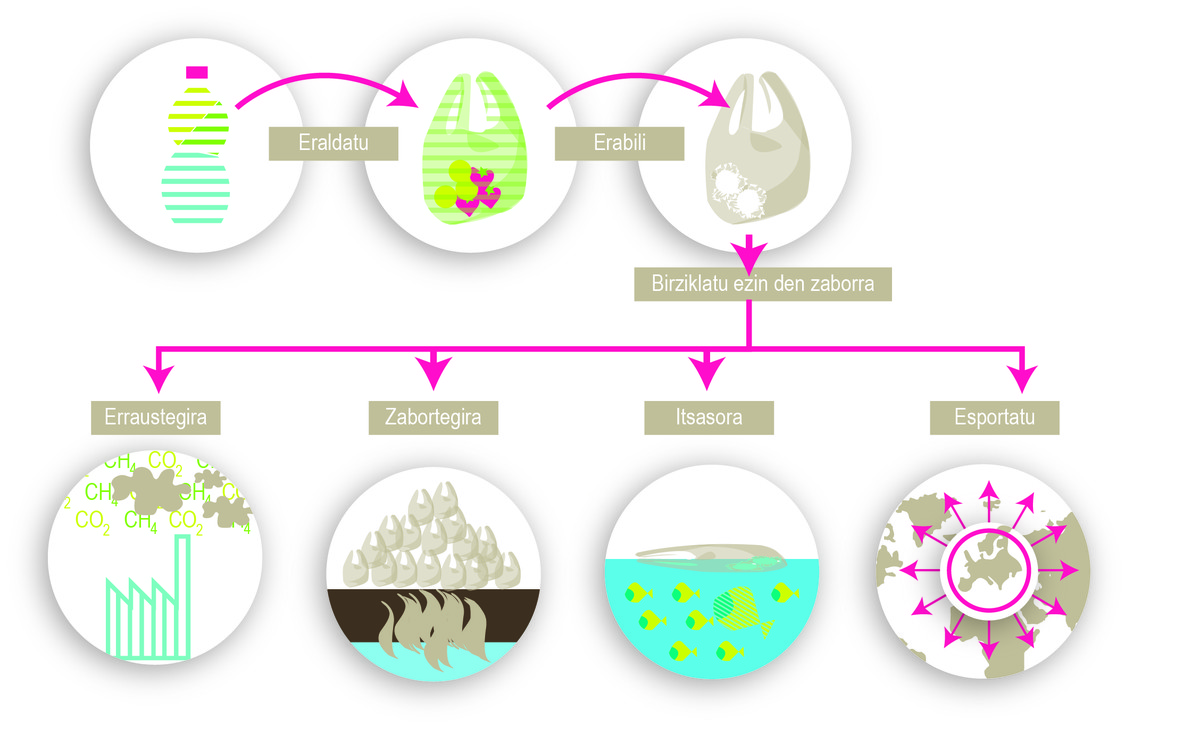

Why not recycle everything we throw into yellow garbage?

When household waste (paper, glass, plastic, metal) is selectively deposited in the containers we separate waste. Thus, in 2016, each inhabitant of the households of the Basque Country deposited an average of 13.20 kg of plastic containers in the yellow container. Although each individual strives to separate the generated household waste, the percentages of improper fractions ending in an unnecessary container are still notable. Most improper fractions are found in containers that collect plastic containers. In 2016, 29.2% of improper waste was collected in the yellow containers of the Basque Country. This hinders the work of waste selective selection plants and their subsequent recycling. Therefore, for the waste to reach the treatment point, it is necessary for each individual to properly separate the waste (Figure 3).

The selective separation of waste therefore facilitates the treatment of waste, but this does not mean that all plastic packaging that is discarded can be recycled. The separation and recycling of plastics is not as direct as the glass and metal recycling process. Since different plastics cannot be recycled together, removing them from the yellow bin from the trash requires identifying and separating plastics. On the other hand, the addition of additives to plastic (stabilizers, pigments, lubricants) allows to find in many occasions plastics of different chemical compositions, stained of food and beverage remains, or other materials (labels of bottles, yoghurt blanket inside the container). This makes it difficult to identify and separate plastic.

Unlike 100% recyclable glass bottles, plastic packaging recycling has limitations. One of them is reuse. For food safety, some types of plastics cannot be reused for food packaging, so the plastic used must be reused. Another boundary is the thermal processes used for recycling plastic packaging. These processes degrade the plastic and cause the loss of material properties in its path. Thus, plastics have a limited recycling cycle, so recycled material must be mixed with the new plastic so that the final product has the necessary properties. All this prevents the production of 100% recycled plastic packaging and forces to produce and use more new plastics to meet consumer demand.

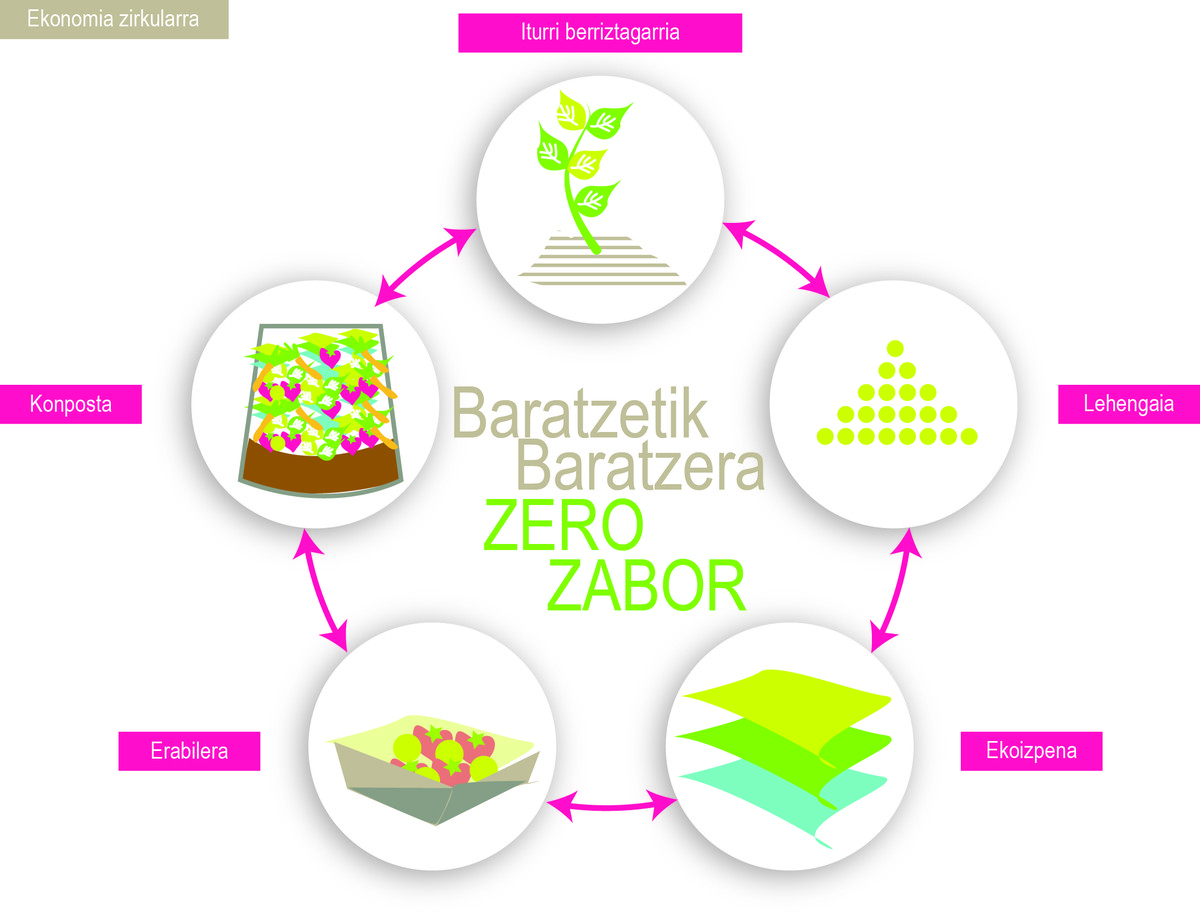

So where are non-recyclable plastics going?

When recycling plastic waste or recycled plastic does not support more recycling cycles, it is used to produce products that have nothing to do with the initial product and that cannot be recycled, such as fabrics, threads, ropes, awnings, packaging, bags, building materials, road asphalt, etc. As an example, PET is used to produce the synthetic yarn used in the textile industry. Thus, a 230 x 180 cm2 blanket with 78 PET bottles was manufactured at the Tzu Chi Foundation. Although a new use is made to the garbage, since the product generated is not recyclable, the garbage ends up in incinerators, landfills and seas or oceans, or moves to other territories (Figure 4).

To address the problem of the volume of plastic waste, waste is intended for incinerators. Although the energy obtained in the combustion process is used as electrical energy and as heat, burning plastic emits carbon dioxide (CO2), methane (CH4) and other greenhouse gases in the air, harmful to the environment and the human being. The part that does not recycle and does not go to incinerators goes to landfills. During the process of degradation of plastic waste, which can last up to 500 years, polluting and toxic compounds are released to the earth's surface and water, negatively affecting nature and human health.

Before landfills are fully filled with waste, plastic waste is transported to other territories. 46% of the plastics collected in Europe for recycling were exported, of which 90% finished in China. During the transport of waste, plastics are lost along the way and end up on the land surface, on the shores of the sea and at the bottom of the oceans. Due to environmental degradation (water, wind, sun) these plastics are broken into small fragments until they become microplastics (< 5 mm). These small plastic particles are consumed by zooplankton and seabirds as food. In addition, zooplankton is one of the basic pillars of the marine food chain, as fish feed on zooplankton, allowing microplastics to end up in the human body through the trophic chain.

Is there a solution for plastics problems?

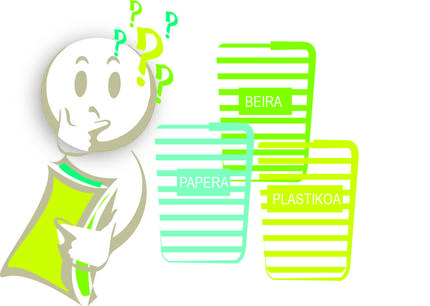

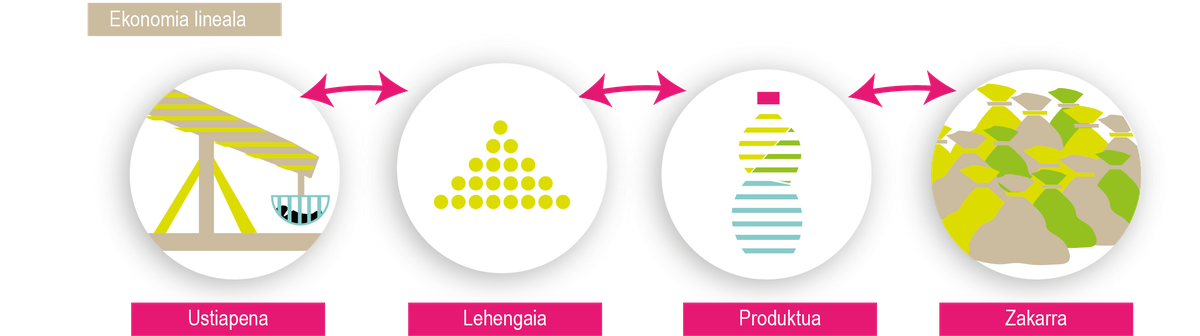

The selective separation of waste is important and necessary, but all this shows that recycling plastic packaging delays the burning of plastic waste or its transfer to landfills, to the sea or other territories. In general, the journey of a plastic container begins to exploit natural resources, after the transformation processes is consumed and ends in landfill. Materials moving in a one-way straight line travel in linear economy (Figure 5). We know that at both ends of this line there are serious problems: the management of final waste and the continued use of the initial extreme natural resources (the growing oil).

Although plastic waste problems are faced with more efficient processes using new technologies, following this linear model is not the best way to give an effective solution to problems. Therefore, with the aim of providing a better solution to problems, it has begun to investigate and produce plastic products containing renewable and/or biodegradable materials (starch, cellulose) in research and development activities. Bio-based plastics are called bioplastics. 0.4% of the 259 plastic MTs consumed worldwide in 2012 were bioplastics and their production is slowly spreading. Bioplastics can be classified into three groups (Figure 6). The industry is betting on non-biodegradable materials from renewable sources or non-renewable biodegradable materials. Although these new paths face one of the problems of the linear economy, the exploitation of natural resources or waste management is still being promoted (Figure 6).

To solve the two problems that arise in the linear economy of plastics, the most sustainable solution is the use of bioplastics made from biodegradable materials from renewable sources. In this model, the final waste is used to produce new products, generating zero waste throughout the entire journey and closing the life cycle of the material. Thus the circular economy model is enhanced (Figure 7). Fortunately, with the aim of providing effective solutions to the problems of plastics, Europe has begun to bet on renewable and biodegradable bioplastics, following the circular economy model. In any case, in a solid, sustainable and effective model that addresses the problems of plastic packaging waste that has begun to expand slowly, it is necessary to create, encourage and strengthen the support and collaboration of individuals, collectives, companies, industries and institutions. Thus, with this circular model, current generations can meet their needs without sacrificing the ability to meet the needs of future generations.

Bibliography

Plastics- the Facts 2017. An analysis of European plastics production, demand and waste data. Food Europe 2016.

Ellen MacArthur Foundation. The New Plastics Economy vs. Rethinking the Future of Plastics. 2016

Ecoembes. Emaitzak 2016. 20 urte of the packaging law, 20 urte of Ecoembes. 2016

DNI Hahladakis, C.A. Velis, R. Weber, E. Iacovidou, P. Purnell. An overview of chemical additives in plastics: Migration, release, fate and environmental impact during their use, disposal and recycling. Journal of Hazardous Materials, 344, 2018, 179-199.

OECD, policies for bioplastics in the context of a bioeconomy 2013. Industrial Biotechnology, 10, 2014, 19-21.

Food and Drug Administration (FDA). Guidance for Industry: Use of recyled plastics in food packaging (Chemistry Considerations), 2006.

D. Lazarevic, E. Aoustin, N. Buclet, N. Brandt. Plastic waste management in the context of a European recycling society: comparing results and uncertainties in a life cycle perspective. Resources, Conservation and Recycling, 55, 2010, 246-259.

J.Q. Jiang. Occurrence of microplastics and its pollution in the environment: A review. Sustainble Production and Consumption, 12, 2018, 16-23.

Related information Velis. Circular economy and global secondary materials supply chains. Waste Management and Research, 33, 2015, 389-391.

L. Giusti. A review of waste management practices and their impact on human health.Waste Management, 29, 2009, 2227-2239.

G. Kaur, K. Uisan, K. L. ONG, C. S. C. Lin. Recent trends in greeen and sustainable chemistry & waste valorisation: Rethinking plastics in a circular economy. Current opinion in green and sustainable chemistry, 9, 2018, 30-39.

European Commission. Closing the Loop against An EU Action Plan for the Circular Economy. Brussels, 2015.

_display_home.jpg)