Paper: grass fibers for new supports

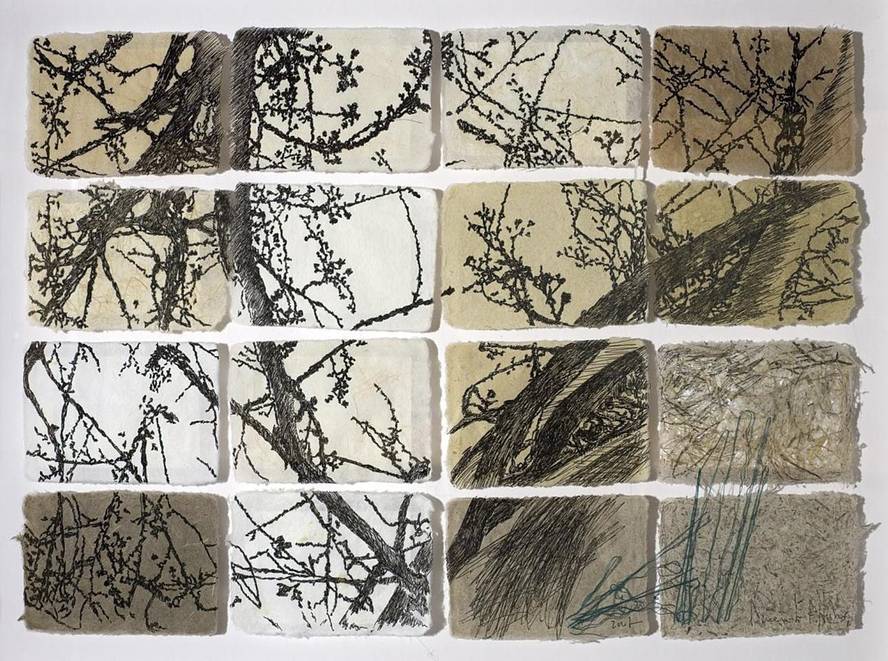

In the artistic context we need to create a new support with different characteristics that give us a new parameter depending on the situation. In artistic creation, the physical characteristics of paper are an important aspect. In fact, they are suitable for various works of art and make representative of thick adjectives, thin, transparent, opaque, weak... Paper can be constructed, broken, sewn, folded, worked, drilled, engraved or manipulated in various ways. Paper fiber can be built in layers, with watermarks, use as paint, pour into molds, carving, etc. Fibers can be left in their natural color or dyed or refined according to the interests of each of them, while other materials other than fibers are added (Allen, 2005). The paper is valid for illustration, printing, painting, collage, photography or sculpture, and can be used in large sizes in multiple formats, installations, assemblies, etc. (Figure 1). Few materials have so many generation possibilities.

In the context of imagery and graphic work, this research is born from the need for practical and analytical research, as well as to answer two questions: Can we develop, work and produce new fiber supports without marketing? What would be its conditions and added value?

With these questions in mind, we have selected some native and allochthonous plants of Euskal Herria that by their characteristics are of interest to our objectives. The selection was based on five aspects:

1. Knowledge development, valuation and prospecting of plant species suitable for use as paper fibres.

2. Study and adaptation of the technological phases necessary for the correct extraction and use of fiber.

3. Evaluation and application of productive processes for the qualitative value of paper.

4. Select the right test and properties to rigorously evaluate results and control quality.

5. Demonstrate the ability to handle itself as support to use it as an artistic element, as an internal structure of graphic images or other procedures. Also, to assess the expressive possibilities offered by the knowledge of the technological treatment used for the manipulation of fibers and the generation of paper.

Prospecting and empirical trials

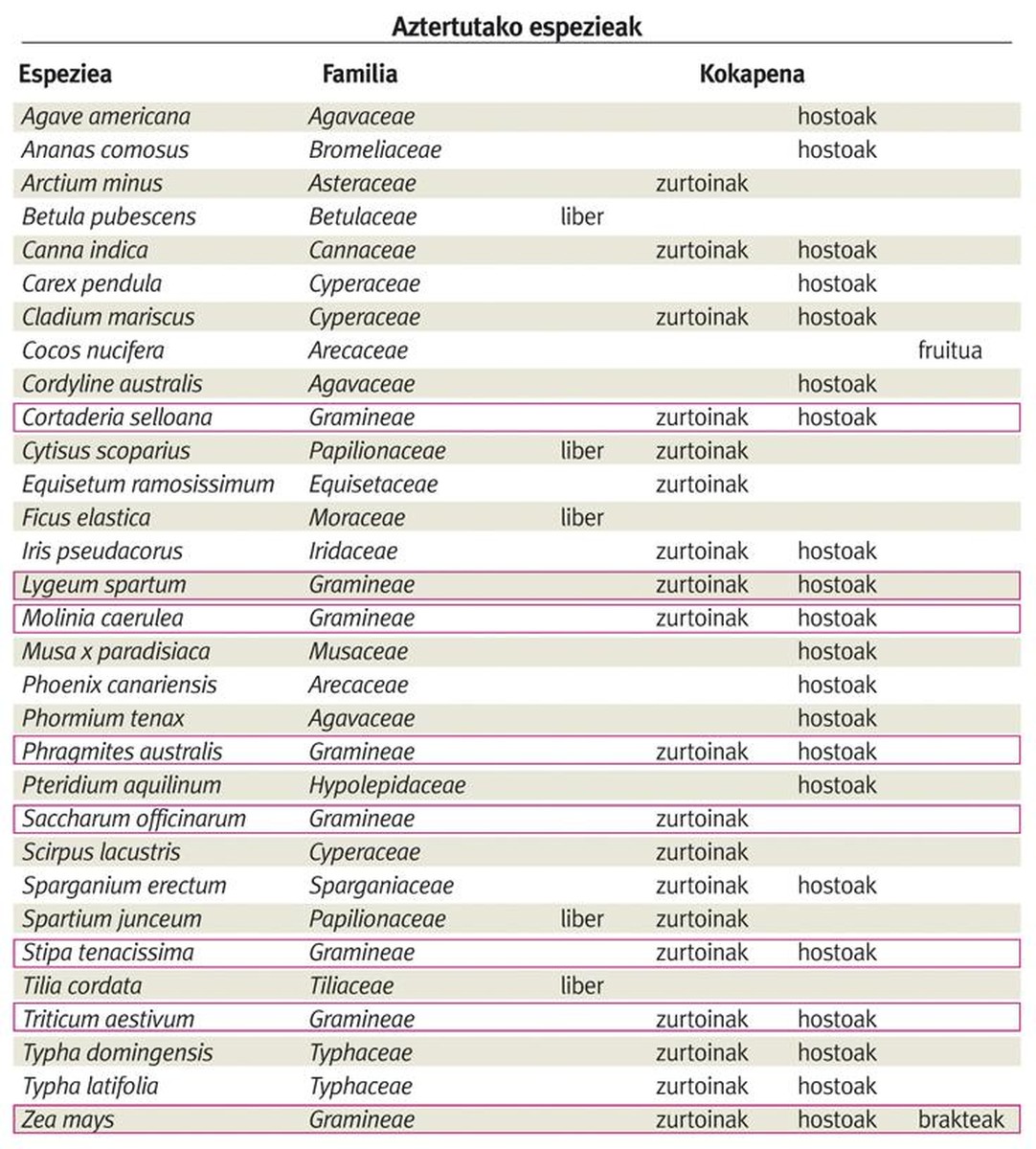

Although we initially rely on the general observation of vascular plants from different communities (forests, undergrowth, meadows, degraded lands, cliffs, wetlands, etc. ), later we modify this decision taking into account the geographical prospecting of nearby species. In most cases they had a history or had similarities in the manufacture of textile fibers or paper. The plant community with the greatest diversity of species has been that of water-related herbs, planted in wetlands, undergrowth, marine banks or exotic gardens. In the first group, the grasses, together with the cyperaceae and the ihias, stand out, of which the papers obtained have shown great diversity. Of the 31 species corresponding to 17 families (Figure 2), the distribution procedure and fiber obtaining were thoroughly sampled.

In general, the following factors were taken into account in fieldwork, sampling and determination of the plants to be used:

1. Taxonomic knowledge and potentially toxic or harmful compounds for health, as well as management problems arising from their consumption as liqueurs.

2. Abundance, regularity and ease of regeneration of the selected herb.

3. Type of productive system described in the literature for obtaining fiber.

4th History of use as paper or textile fiber.

5. Evaluation of other uses related to the plant.

6º Taxonomic proximity to the species described, used as paper fibres.

7. Abundance of profitable sclerenes in processes and consumptions.

8th. Possibility to use different parts of the plant.

9. Easy to extract the fiber from the plant.

10. Have a suitable place to facilitate the obtaining of the plant.

11. Bring new results in this field of research.

Results and debate

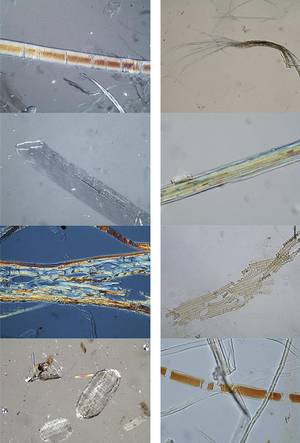

The fibers constitute the skeleton or structure of a sheet of paper (Figures 3-5), so they must have specific characteristics for the use or application that is intended to be achieved. Although theoretically any plant can become paper, in practice this hypothesis is less viable (Hunter, 1947), since we must take into account the morphological or histological characteristics of plants. On the one hand, not all plants have the same amount of fibres or the same quality of paper making, and on the other hand, we must take into account the growth biotope, the time of plant collection and the abundance and availability of the species present in nature.

Other aspects to consider in the manufacture of paper are the relative homogeneity in the direction or disposition of the fibers, their quantitative or qualitative abundance and the resistance and prosperity of the bridges between the fibers. In addition, it is important to know that, although the factors influencing the bridges between the fibers depend on their physical and chemical characteristics (mainly hemicellulose and lignin) and their location in the plant (Atchison & McGovern, 1987), subsequent processes (bleaching, refining, pressing on moisture, calendering or adding additives, among others) (1998).

Handmade papers in this technical-artistic context must meet a number of requirements: be homogeneous, be smooth or ductile, sometimes opaque and sometimes transparent, have a stable dimension, be uniform to absorb ink, as well as be resistant to tensions and stay in time. In addition, the variety of shades, the control of the texture and the different finishes with each fiber motivate us. In short, the macroscopic and microscopic control of the species to be tested motivates us. (Figures 6-13). These characteristics will only be possible through exhaustive analysis and manual paper processing through a technical process (López-Quintana & Legarreta, 2008).

To ensure good results in the selection of plant species, the basic characteristics necessary for the correct development of the product were established as raw material. These include:

A. Paper morphological study or observation of plant anatomical elements.

B. Comparison of the biometric analysis of the sequences of the three refining systems used: disintegrator, ball mill and Dutch pile.

C. Physical trials. We have quantified weight, thickness, density, softness, hardness and porosity, tear tests, whiteness, opacity and color, dimensional instability, capillarity or degree of filtration.

D. Mechanical tests that have analyzed the suitability of new papers for the processes to be performed.

The results obtained have determined the behavior of the eight products and the variables that affect the improvement of their quality. The selected plants are: Cladium mariscus, Cortaderia selloana, Iris pseudacorus, Lygeum spartum, Phragmites australis, Spartium junceum, Typha domingensis and Zea mays (Figs. 14-15).

Conclusions

The variability of the length of the fibres of the different species, as well as of the different organs of the same plant, has allowed the creation of numerous paper products, as is the case of Zea mays. In the prospecting section we highlighted the capacity of Cladium mariscus, a new species that has not been previously studied in this field of research.