No more cracks in 3D metal printing

3D printing with metals would be a real industrial revolution, as the possibilities of metallic design would increase greatly. In practice, however, very few metal alloys can be used, as the fusion and solidification dynamics of 3D printing cause the material to crack. Scientists have just solved the problem by introducing nanoparticles that control solidification in the layer metal addition process.

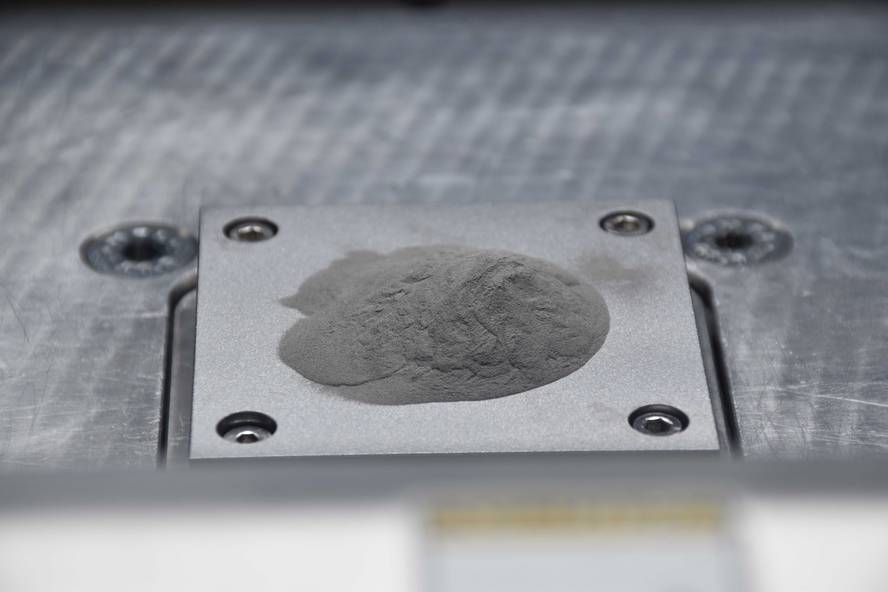

Hydrogen stabilized zirconium nanoparticles have been used, in this case to coat high-strength aluminum alloys. The new methodology, presented in the journal Nature, has shown that the pieces printed with the help of nanoparticles are not cracked and have a solidity equivalent to forging materials. Although this methodology has been developed with aluminum alloys 7075 and 6061, it has been highlighted that it can be applied to other alloys.