New energy accumulators based on magnetoelectric composites

Euskal Herriko Unibertsitateko irakaslea Elektrizitatea eta Elektronika Sailean

The current society demands the use of devices of low energy consumption increasingly small and useful. Magnetoelectric composites, capable of inducing electrical voltage under a magnetic field, can be used to feed new systems of low consumption by coupling between magnetic and electrical properties.

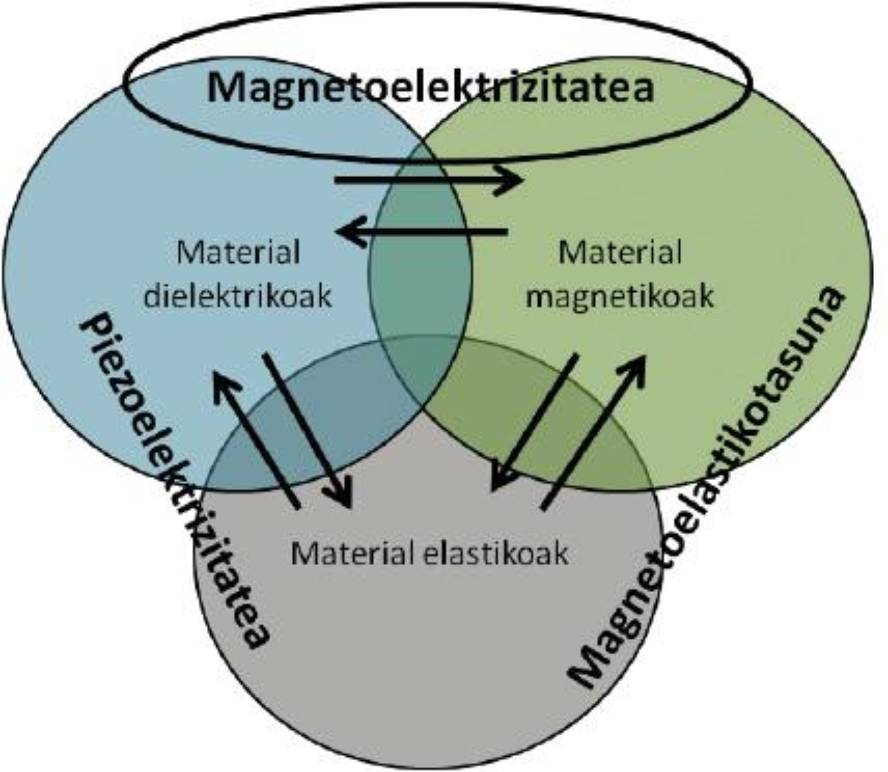

Magnetoelectric composites have evolved notably in recent years in energy accumulators. These composites, in general, are formed by magnetostrictive material and piezoelectric material (materials that are deformed under a magnetic field and materials that induce electrical voltage when suffering a deformation, respectively). Therefore, when applying a magnetic field on these composites, the magnetostrictive component is deformed. This strain is transmitted to the piezoelectric component inducing electrical voltage. This effect is called magnetoelectric effect and is used in many applications [1].

The magnetostrictive components used in magnetoelectric composites are metal alloys in the form of sheets made of iron and/or cobalt. As piezoelectric components, ceramic STP is usually used as a film or PVDF polymer. Although STP has a better piezoelectric response, it is a very fragile material and can cause problems in some applications. The PVDF polymer presents a lower, but more adaptable, piezoelectric response with better behavior in practical applications.

In magnetoelectric composites, the highest signal induced around the resonance frequency of the composite is obtained. The resonance frequency is inversely proportional to the length of the magnetostrictive component. Therefore, the longer the composite is, the lower the resonance frequency.

Magnetoelectric composites as energy accumulators

The manufacture of magnetoelectric composites requires a certain combination of magnetostrictive and piezoelectric materials. To select the materials most suitable for its manufacture, the properties of each element should be analyzed. For magnetostrictive materials, alloys of the type FeCoSiB are usually used, among others, due to their excellent magnetic properties. As a piezoelectric material, an appropriate option is the piezoelectric polymer PVDF, which presents the highest piezoelectric response among piezoelectric polymers. To couple the magnetostrictive and piezoelectric properties, it is usual to use an epoxy resin. Taking advantage of this epoxy, a sandwich composite is made with two magnetostrictive plates glued on both sides of a PVDF film of the same length.

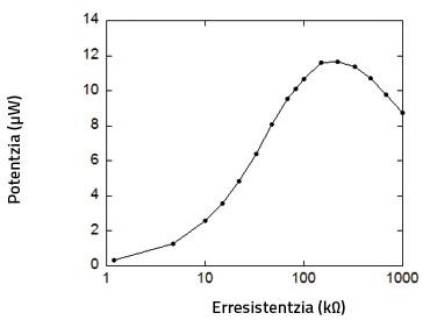

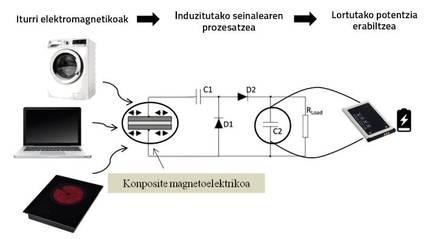

To obtain the power provided by the composite Fe 61.6 Co 16.4 Yes 10.8 B 11.2 /PVDF/Fe 61.6 Co 16.4 If 10.8 B 11.2 of 3 cm in length, for example, it is necessary to first measure the resonance frequency of this composite, at which point is the highest magnetoelectric response of the composite. In this specific composite, the resonance frequency is at 50 kHz. Therefore, the use to this frequency of the alternating electrical signal induced in the composite requires that the alternating voltage becomes direct voltage, for which the induced signal must pass through a circuit of multiplication of voltage [2]. From this direct voltage, the power provided by the magnetoelectric composite can be calculated based on the resistance coupled in the circuit.

The maximum power obtained from the circuit is 11.6 µW for a resistance of 220 kiloohms. This value is totally comparable to other energy accumulators that appear in the bibliography, where similar powers have been measured [3] using STP and piezoelectric materials (better piezoelectric response).

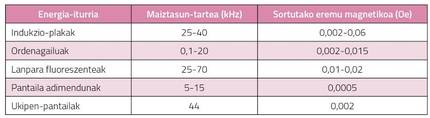

However, the use of energy accumulators in everyday life requires the substitution of generators used in laboratories for the resources that the environment offers us. These resources, of course, must meet some requirements. For example, they must create a magnetic field whose frequency must be placed in a given range (at the resonance frequency of the corresponding composite) to induce a sufficient voltage in the magnetoelectric composite.

Taking into account the resonance frequency of the magnetoelectric composite Fe 61.6 Co 16.4 Yes 10.8 B 11.2 /PVDF/Fe 61.6 Co1 6.4 If 10.8 B 11.2, induction plates, computers or smart displays could be used as generators, among others. The use of magnetoelectric composites of different sizes or compositions alter the resonance frequencies, so it would be necessary to search for electromagnetic sources that work in other frequencies to obtain the maximum power of the composites.

Influence of size on power

As mentioned in the introduction, the size of the devices is as important as the utility. Manufacturing smaller and smaller devices is one of the objectives of today's industry and society. Therefore, in the case of magnetoelectric composites, it is also necessary to analyze the influence of the reduction of devices on the supplied power. In the case of magnetoelectric composite Fe 61.6 Co 16.4 Yes 10.8 B 11.2 /PVDF/Fe 61.6 Co 16.4 If 10.8 B 11.2, 1 and 0.5 cm systems provide power of 0.28 and 0.06 ?W, respectively. Therefore, if you want to get energy from smaller magnetoelectric composites, you have to take into account that they will provide a much lower power, and depending on the application you will have to decide whether it is sufficient or not.

Applications in new technologies

As can be seen, these new magnetoelectric composites are capable of achieving a power of microwatts. This power, although it seems relatively low, can serve for use in new technologies. For example, pacemakers placed in the body to control the heart rhythm need 10 ?W to function. The wireless sensor network uses a similar power to monitor temperature, control chemical pollution in cities or pressure of cars [6]. Wireless communication networks are used in many other low-consumption applications. For example, devices that are located in the body often use this type of networks to communicate with each other (known in English with WBAN letters).

In addition to communications, the energy generated by magnetoelectric composites can be used in other fields. This energy can also be used to replace the batteries of our mobile or other small devices. In fact, mobile phones have been manufactured without battery [7]. This type of mobile takes energy from the light or radio signals of the environment.

It is evidenced, therefore, that the new technologies of the future require energy types of low consumption, easy to get and wireless. In this route, magnetoelectric composites are expected to have an important influence on the research being carried out on this type of new materials. These devices, in addition to obtaining energy from the environment, are able to generate the power necessary to feed small devices. New energy accumulators for new technologies!

Bibliography Bibliography Bibliography

Work presented at the CAF-Elhuyar Awards.