Develop a new procedure to obtain hydrogen

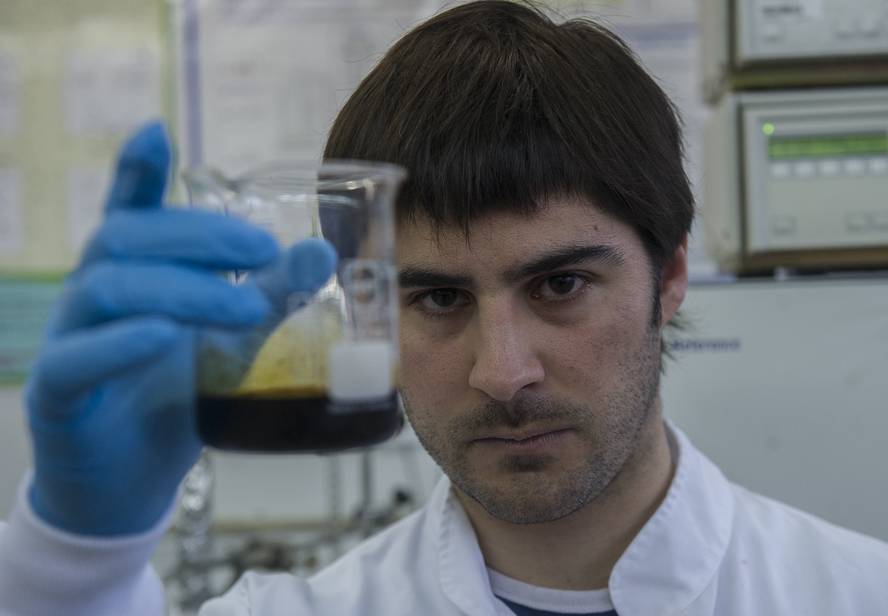

Chemical engineer Aingeru Remiro has developed a process of extracting hydrogen from biooil in his doctoral thesis presented at the UPV. This process has a lower environmental impact than the current pathways of obtaining hydrogen.

The methods of obtaining hydrogen currently require the separation of hydrogen from other chemical elements, both carbon (fossil fuels) and oxygen (water). The methods used are not viable for the mass production of hydrogen, in the case of carbon from the environmental point of view, and in the case of oxygen from the economic point of view.

Remiro has developed a laboratory scale process for the extraction of hydrogen from biooil through catalytic water steam reformation. Biooil is a heterogeneous mixture of oxygenated products, with origin in wood, and its catalytic transformation often generates problems of operativity and deactivation of the catalyst. In fact, when heated, a fraction of the compounds that are part of the biooil form a solid sand (called pyrolytic lignin) that accumulates in the inlet tubes to the reactor and in the reactor itself.

To solve the problems arising from the use of biooil, a two-stage, thermal and catalytic reaction equipment has been used. In the thermal stage the biooil is heated and it is proceeded to the controlled deposition of the pyrolytic lignin. The resulting compounds are easier to transform and reduce the problems of pyrolytic lignin. In addition, Remiro has added a third stage: Capture of CO2. He has done so using an adsorbent on the reaction bed. “By eliminating CO2 from the bed of reaction, we facilitate the displacement of reaction balances, achieving higher performance and higher hydrogen production,” says Remiro.