[Microbes and surfaces: problem and solution?].

With COVID -19 infectious diseases have become daily news. However, concerns about these diseases are pre-existing, as microbes are developing constant resistance to antibiotics. Other future strategies are therefore being investigated. Among them, it is known that surfaces are of great importance in the spread of certain microbes. So if we had surfaces suitable for different environments to deal with microbes, we would be on the way to limiting the problem. To this end, Tecnalia and Cidetec Surface Engineering collaborate in research and development of new opportunities in this field.

_article_big.png)

In the form of parasites, bacteria or viruses, microbes cause many diseases. Until antibiotics appear, most people die throughout history from infections. Today, thanks to their mutations, microbes are developing increasing resistance to antibiotics causing 33,000 deaths a year in the European Union.

In addition to prophylaxis and more rigorous therapies, research is carrying out numerous studies with the aim of developing new antimicrobial tools. It is known that the surfaces of the surrounding objects play an important role in the microbial spread. Consequently, many research studies have as their objective the development of antimicrobial surfaces. In general, these investigations follow two main strategies: on the one hand, avoiding microbial adhesion and expansion in contact with surfaces or killing microbes, and on the other hand, releasing antimicrobial agents from surfaces to act on the microbes in the environment. Both strategies have their own advantages and limitations. For example, one of the limitations is that an effective amount of antimicrobial agents cannot be released from surfaces for as long as desired. In addition, if a smaller amount is released than is distressing, microbes can develop resistance to these agents, while if the amount is high, toxicity problems can occur in living beings around them.

In this area, in Tecnalia, several lines of research have been initiated in recent years. On the one hand, and based on the technologies magnetron sputtering and sol-gel, we are working on the development of antimicrobial coatings. At the same time, procedures have been developed to verify and measure the effectiveness of these surfaces, such as in vitro (Figure 1) or recent antivirus, and in vivo in collaboration with physicians from BioDonostia and Osakidetza. On the other hand, their efficacy time has been evaluated, for example, in relation to wear, corrosion or cleaning products and sterilization procedures.

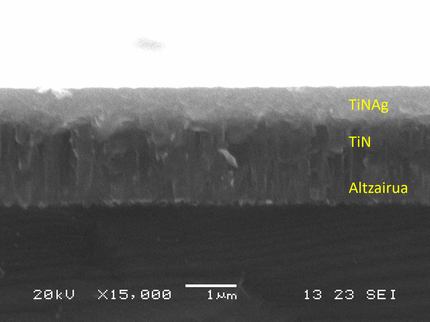

By the magnetron sputtering technique, thin coatings can be applied on selected surfaces and, if desired, different overlapping layers. In the field of metals it is known that, for example, silver (Ag) and copper (Cu) may be affected, in good condition, by antimicrobial action. With these characteristics, hard layers doped with silver and copper have been developed in Tecnalia. Hardness gives coating anti-wear properties. For example, it can be done with hard nitrides.

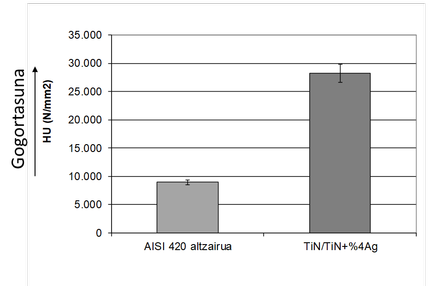

Research has enabled the development of different Masders families, suitable for different cases. For example, in the case of coatings formed by layers of titanium nitride (TiN) and silver doped titanium nitride (TiNAg), the first layer of TiN considerably increases the intrinsic hardness of steel (triplicarla); if a small percentage of silver, TiNAg, is added in the superimposed layer, a wide spectrum antimicrobial effect can be achieved. Furthermore, it has been shown that this layer has no toxicity according to ISO 10993 standard. The amount of silver it gives is not harmful to neighboring cells. On the other hand, friction values with silver are also lower. (Figure 2).

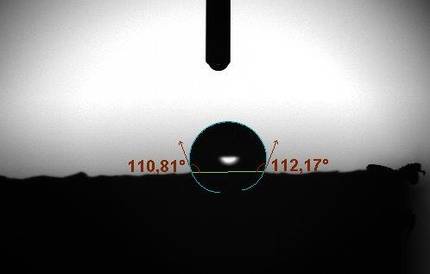

In the case of Cidetec Surface Engine, the main strategy is to minimize microbial retention by developing surface low energy and high slip coatings (Figure 3). In the case of bacteria, these coatings help inhibit biofilm formation. In particular, they are coatings with free or framed polymeric chains, with specific functional groups (silanes, phosphonates or epoxy groups), which allow covalent anchorage on substrates. These chains may be completely or partially fluorinated, or without fluorine atoms, for example, polysiloxan-based chains.

For its part, Cidetec Surface Engine {\} develops coatings with combined low adhesion properties and biocidal effect to produce synergistic effects that provide greater antimicrobial capacity. This includes the species loaded in the initial formulation of low adhesion coverage, or as subsequent functionalization. Photocatalytic agents, both organic and inorganic, with energy absorption capacity in the visual field of ultraviolet light (UVA) are also used.

In conclusion, it is clear that the surfaces around us in everyday life play an important role in the spread of microbes and, therefore, infections. However, the risk can become a solution if we are able to develop suitable surfaces.

In this respect, Tecnalia, Cidetec Surface Engine and other partners (Elkartek ?-2021/00124) have launched the FRONTIERS 21 research project. The aim of the project is to develop new scientific knowledge and capabilities in the field of surface technologies, antibacteria and antivirus, both for medical and industrial use.

References.

[1] Arciola C.R., Campoccia D. Montanaro L. 2018. “Infections app: adhesion, biofilm formation and immune evasion”. Nat. Rev. Microbiol. 16, 397–409. https://doi.org/10.1038/s41579-018-0019-y

[2] Braceres I. Álvarez N., Martínez Van Geeteruyen M., Brizuela M. 2021. “TiN-Ag as an antimicrobial and wear coating”. Biotribology 28, 100192. https://doi.org/10.1016/j.biotri.2021.100192

[3] Campoccia D., Montanaro L. Renata Arciola C. 2006. “The significance of infection related to orthopedic devices and issues of antibiotic resistance”. Biomaterials 27, 2331–2339. , https://doi.org/10.1016/j.biomaterials.2005.11.044

[4] Cloutier M., D. Mantovani, Rosei F. 2015. “Antibacterial coatings: challenges, perspectives, and opportunities”. Trends Biotechnol. 33-11, 637–652. https://doi.org/10.1016/j.tibtech.2015.09.002

[5] D.O. Davidson, D. Spratt, Liddle A.D. 2019. “App materials and prosthetic joint infection: the battle with the biofilm”. Effort Open Rev. 4, 633–639. https://doi.org/10.1302/2058-5241.4.180095

[6] Jung W.K., Koo H.C., Kim K.W. Shin S. Kim S.H. Park Y.H. 2008 Antibacterial activity and mechanism of action of the silver ion in Staphylococcus aureus and Escherichia coli. Pl. Environ. Microbiol. 74, 2171–2178. https://doi.org/10.1128/AEM.02001-07

[7] Katzenberger R.H., Rösel A. and Vonberg R-P. 2021. “Bacterial survival on inanimate surfaces: a field study”. BMC Res. Notes 14:97, 1-10. https://doi.org/10.1186/s13104-021-05492-0

[8] Moriarty T.F. Kuehl R. Coenye T. Metsemakers W.-J. M. Morgenstern, M. Schwarz E. Riool M. Zaat S.A.J. Khana N., Kates S.L. Richards R.G. 2016. “Orthopaedic?related infection: current and future interventions for improved prevention and treatment, Effort Open Rev. 1, 89–99. https://doi.org/10.1302/2058-5241.0037

[9] Romanò C.L., Tsuchiya H., Morelli I, Battaglia A.G., Drago L. 2019. “Antibacterial coating of implants: are we missing something?” Bone Joint Res. 8, 199–206. https://doi.org/10.1302/2046-3758.85.BSOLE-2018-0316

[10] Watson R., Oldfield M. D. Bryant, Riordan L. D. Hill H.J., D.O. Watts Alexander M.R. Cox M.J. Stamataki Z. Slim D.J. and Cogan F. 2022. “Efficacy of antimicrobial and antiviral coated air filters to the spread of airborne pathogens” Nature portfolio, scientific reports 12, 2803. https://doi.org/10.1038/s41598-022-06579-9