Three-phase electric vehicle inverter: eternal incognito

In the exciting world of electric vehicles, where batteries and motors are often talked about, the power inverter often remains on a later plane, even if it is a key agent. This element is usually left out when talking about the autonomy and performance of electric vehicles. But the inverter is a fundamental device for electric propulsion, as it turns the current from batteries into alternating current to drive the vehicle.

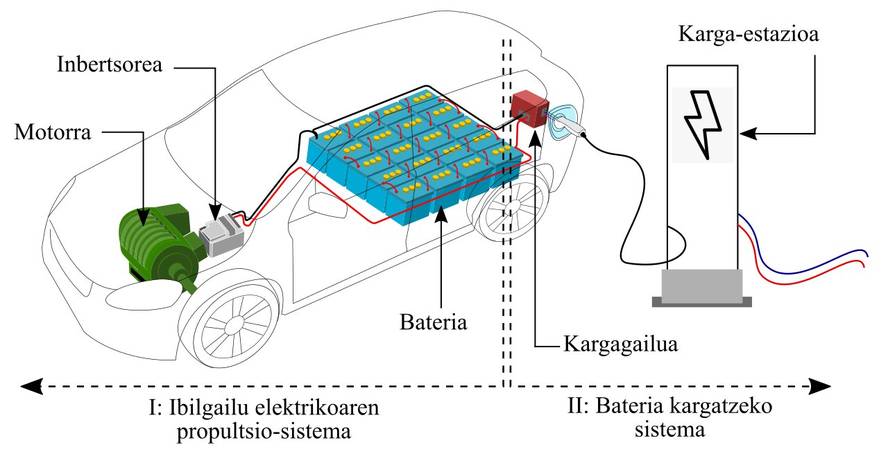

The propulsion system of an electric vehicle consists mainly of three components: battery, power inverter and electric motor. Some vehicles may replace batteries with hydrogen batteries or, in hybrid non-plug-in vehicles, the electric charger may be left aside. However, it is essential to note that all electric traction vehicles have a drive consisting of an electric motor and a power inverter.

The battery stores the energy required for the operation of the vehicle, lithium ion (Li-Ion) and lithium ferrophosphate (LFP) batteries currently predominate. On the other hand, the electric motor functions as a traction element to transform electrical energy into mechanical energy. The main motor technologies are permanent magnets synchronous machines (PMSM) and induction machines (IM) [1, 2].

As for the investor, it plays a key role in transforming the DC into AC, the form of energy used by the electric motor. Although each component of the propulsion system plays an essential role, there is a tendency to disregard the importance of the investor, but its contribution is also decisive. Without it, it would not be possible to transform the energy stored in the batteries into a form that can be used by the electric motor.

Power inverter

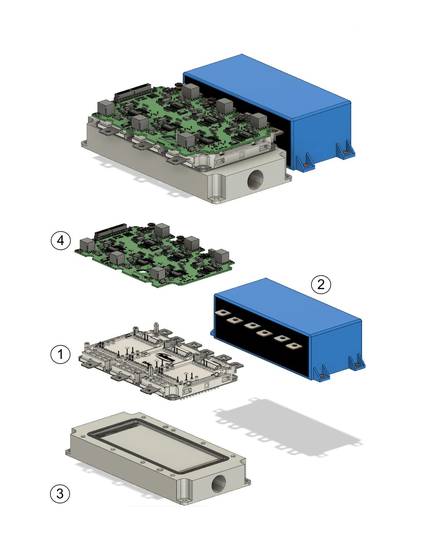

The inverter can be considered a central element of the propulsion system, as it controls the two-way energy flow between the battery and the electric motor and acts as a means. The investor consists of several parts:

- Power module. It's called the electric heart of the vehicle. This module includes power semiconductors such as MOSFET and IGBTs. They fulfill the role of electronic switches that control the flow of electric current. Fast switching (in IE 10-20 kHz) optimizes system performance. Robles et al. In the 2022 work [3] we carried out a thorough analysis of the alternatives and technologies of power modules and semiconductor devices.

- DC Bus Condenser. The power inverter has a DC bus connection, which may contain one or more capacitors. In some way, capacitors manage to decouple the battery inverter, softening the waveforms (current and voltage) due to switching power semiconductors. Among the technologies, metallic polypropylene film capacitors are preferred in electric vehicles for safety and robustness. We analyzed in detail the technology of these reactive elements, Matallana et al. Working in 2019 [4].

- Cooling. Thermal management is essential to ensure the performance and life of power semiconductors of electric vehicles. In the case of investors, the simultaneous presence of currents and voltages produces heat when power losses occur, which has an impact on the useful life of semiconductors. Air cooling systems are easily implementable, but sometimes do not meet the demands of the automotive sector. Most manufacturers prefer liquid cooling solutions as they offer higher thermal dissipation. We conducted an exhaustive review of these heat extraction methods, Robles et al. Working in 2022 [3].

- Driver card. This element is mostly composed of digital circuits and acts as the system's "brain", controlling power semiconductor switching. It's important because it synchronizes semiconductors on and off. In addition, it continuously monitors the temperature and current of the power modules, thus ensuring system safety.

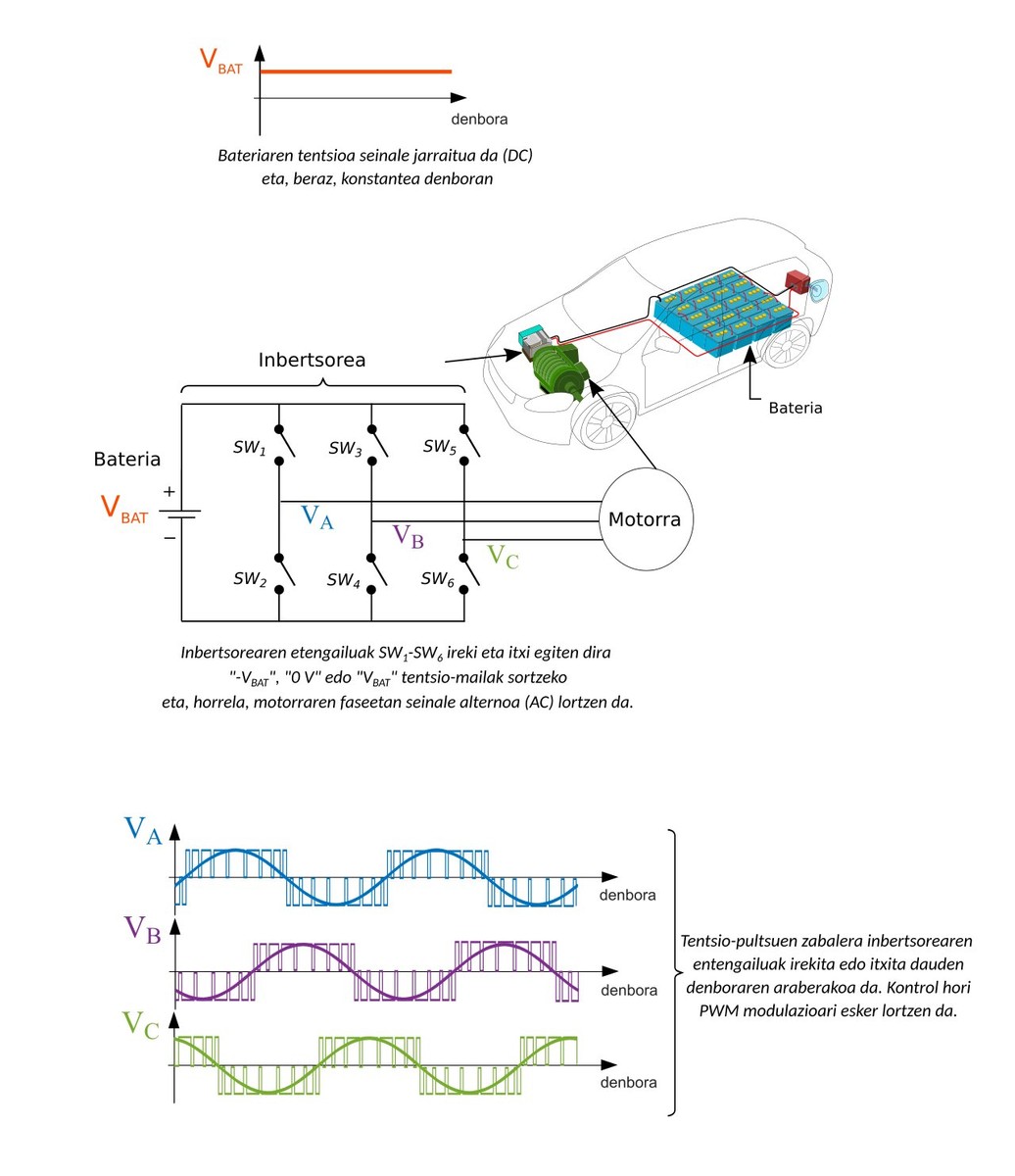

Operation of the power inverter

To understand the functioning of the investor, it is useful to describe it as a translator. Imagine that the battery and the engine are two people who speak different languages. The inverter acts as a translator between the two so that the battery and the motors are understood as if they were in the same language. But technically, how does an investor work?

The pulse width modulation (PWM) technique [5] is used to control the speed of an electric motor in investors. This technique works by changing the duration of the tension pulses sent to the motor. The high switching speed allows the motor to filter this signal, obtaining sinusoidal currents and spinning the motor without producing "electric noise". When lower velocity is desired, tension pulses are shorter, while for higher velocity they are longer. This generates less amplitude sinusoidal currents.

Engineering challenges and developments

Over time, investor engineering has driven significant advances to address the challenges. Bipolar junction transistors (BJT) initially allowed current switching, but performance was not the best in speed and efficiency. Later, the creation of the transistors MOSFET (1959) and IGBT (1979) met these challenges, achieving greater efficiency, speed and energy transformation capacity. The implementation of pulse width modulation (PWM) improved investor output control and managed to reduce energy losses. Moreover, digital control, improving the first processors invented in the 1970s, improved the dynamic response as it moved to the next-generation DPS and FPGA chips. These advances have transformed the management of electric power and all kinds of applications (wind, machine-tool, rail traction) have allowed the massive use of the investor in modern applications, even in electric vehicles.

Future trends and innovations in power investors

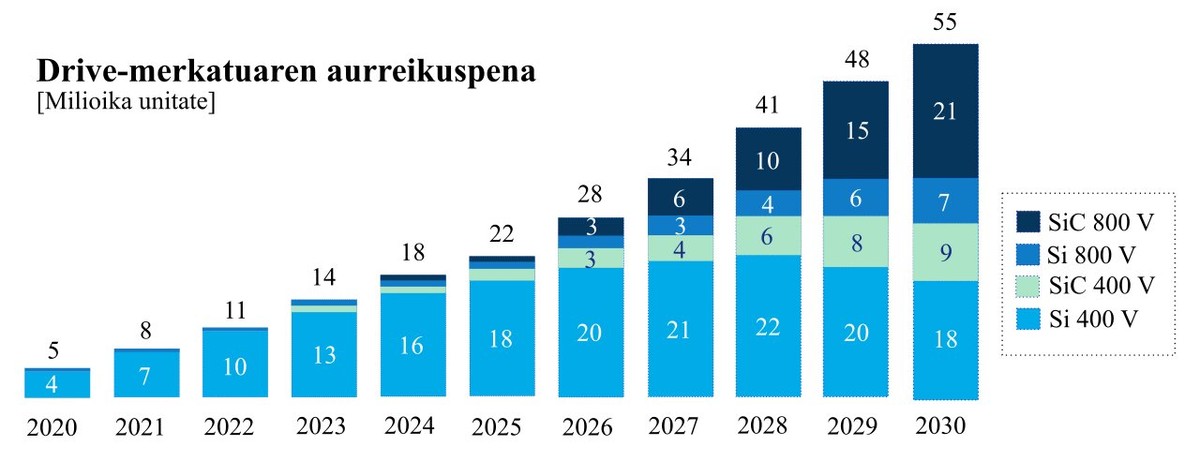

One of the main trends of electric vehicles is the optimization of power density. Engineers work hard to make investors stronger and lighter in weight to get more efficient and dynamic electric vehicles. This directly affects autonomy, achieving a higher level of autonomy, offering greater freedom of driving to users and reducing concerns related to battery recharge.

The incorporation of new Silicon Carbide (SiC)-based semiconductors into investors, more efficient than Silicon (Si), is essential to achieve these benefits. The introduction of SiC semiconductors enhances the durability and reliability of investors as they are stronger.

Moreover, the evolution towards faster and more efficient load systems alters the perception of recharge of electric vehicles. Fast charging capacity and new investor developments will enable drivers to load their vehicles more quickly, removing the obstacles associated with charging time and improving the daily practice of electric vehicles.

In this regard, the arrival of 800 V batteries is revolutionizing the fast charge and improving the efficiency of investors. These voltage levels allow a faster load and allow for more efficient and robust motors, giving drivers more autonomy and driving experience.

In addition, the Vehicle-to-Everything (V2X) technology, which allows the transmission of stored energy in the battery of electric vehicles to all devices, stands out as a transformative innovation in investors. This technology allows drivers to use the energy of their vehicles flexibly, as they will be able to charge or power electronic devices away from home.

In conclusion, it can be said that future trends in electric vehicles and power investors are interrelated and that in the future electric mobility, as well as being sustainable, will be more accessible to all. From increased autonomy to faster load times, the integration of innovative technologies is shaping a promising situation that will transform electrical mobility.

Contribution of the Basque industrial sector

The Basque industry has become a benchmark in innovation and technology, especially in the development of propulsion systems for electric vehicles. Clusters of companies CIE Automotive, JEMA Energy, Irizar/Creatio, GKN Driveline, CAF and ACICAE, among others, have been of vital importance for their close collaboration with manufacturers (OEM) and global suppliers to drive advances in electrical propulsion systems.

Ingeteam or JEMA’s expertise in advanced semiconductor technologies and smart control strategies has consolidated the Basque industry as a leader in this sector. Technological centres Tecnalia, Tekniker and Ikerlan have also made an important contribution to progress through innovative research in battery management systems. These are essential to optimise the performance and durability of propulsion systems.

For our part, the members of the APERT research group of the UPV/EHU remain committed to excellence, working actively in energy converters and control circuits. Together with leading companies in the Basque industry, we work on improvements in such important elements as the electric vehicle power inverter and contribute to future sustainability on a global level.

Bibliography

[1] LÓPEZ, I. ET AL (2019). Next generation electric drives for HEV/EV propulsion systems: Technology, trends and challenges. Renewable and Sustainable Energy Reviews, vol. 114, pp. 1-23.

[2] ARETXABALETA. I. ET AL (2021). High-voltage stations for electric vehicle fast-charging: trends, standards, charging modes and comparison of unity power-factor rectifiers. IEEE Access, vol. 9 pp. 102177-102194.

[3] ROBLES, E., ET AL (2022). The role of power device technology in the electric vehicle powertrain. International Journal of Energy Research, vol. 46, ez 15, pp. 22222–22265.

[4] MATALLANA, A., ET AL (2019). Power module electronics in HEV/EV applications: Technologies and design aspects. Renewable and Sustainable Energy Reviews, vol. 113, pp. 1-33.

[5] FERNANDEZ, M., ET AL (2023). Proposal of discontinuous technique for five-phase inverters under open-phase fault operation, Machines, vol. 11, ez 3, pp. 1-13.

[6] ROBLES, E. (2022). Other potential, electric vehicles device tracking the other operation remains. Doctoral thesis UPV/EHU.