LED. Change of light

The light emitting diodes, the LED lights, have occupied the streets of the CAPV instead of the conventional light bulbs, which are mostly found in the traffic lights. The main change has occurred in the last two years. In Bilbao, Vitoria and San Sebastián, for example, in 2010 traditional light bulbs were replaced in traffic lights. There are still some, but very few. Prevalence of LEDs. And the traffic lights are just an example. "The revolution is taking place now," says CEIT engineer Gemma García.

And in the public lighting the LEDs still have much to colonize. As can be seen in many cities of the world, if the current trend is maintained, they will soon be located in streetlights, tunnels, public parking, etc. The small towns have been great testers of this type of facilities. In Tolosa, for example, is the street Pedro de Tolosa illuminated by LEDs.

On the other hand, in most major European cities, LED lights have been used to illuminate some streets: Paris, London, Berlin, Prague, Warsaw, Amsterdam and many more. In the Netherlands, a seven-kilometer stretch of the A44 motorway has been illuminated by LED lights. And in Istanbul, the Bosforo bridge road is also illuminated by LED. In the United States, the city of Raleigh, in North Carolina, was one of the first to do the test and, due to its success, LED lighting has already been expanded in the street, as is the case of New York and Washington. The list is long and the overall results are good.

Old LED, new hero

The LED lights consume little and last a lot, so they are so successful. Although they are not cheap, the cost of the facilities is amortized for a few years. And it has other advantages.

To some extent, the advantages of LEDs can be summarized in negative. It does not generate heat, since it converts most of the energy it spends in light. It has no fragile pieces like the thin thread of the bulbs. It is not made up of dangerous or harmful substances for the environment. The advantages are remarkable.

And the invention is old: The LED was invented in 1927 and entered the industry in the 1960s. Why have they not been used before? It must be said that for some applications it began to be used almost 50 years ago. Since then the red light indicating that a machine or switch is on has been the LED. And they have also been used to create ancient electronic numbers of seven segments. In both cases, however, the LEDs were red, and that is the answer to the question. They have not been used previously for any other use since there was no LED of other color. The first ones were red; then, in the 1970s, they developed green, orange and infrared LEDs; and the turning point in the manufacture of LEDs dates back to the 1990s, when Japanese researcher Shuji Nakamura first achieved the manufacture of blue LEDs. García recalls that era perfectly: "I was finishing the race at that time and the professor of Electronic Technology told us. “They will pull out the blue LED!” he said.

The key was the material. LEDs (Light Emiting Diode) are diodes, a device that acts as a switch, electrons need a minimum voltage to overcome an energy cut, jump in some way and have current in the circuit. In LEDs, electrons emit light when combined with positive loads at the end of the jump. In some materials the jump is greater than in others. "Depending on the material you use, the combination of electrons and positive charges emits a light of one wavelength or another," explains García. The more I jump, the more "blue" is the light emitted. And the size of the jump depends on the material of the diode. Therefore, to get new colors, the researchers had to find suitable materials, and in this exploration Nakamura was the first to find material to produce the blue LED: Gallium nitride.

LED White

The color of the bottle is blue. In addition to developing blue LED, he has also worked with blue laser, which has been the basis of Blue-Ray technology (and old HD-DVD). However, in the history of technology the name of Nakamura will be primarily associated with the development of blue LED. He also developed an ultra-violet --energy LED even higher than blue, such as the one used to disinfect water, but with less echo than blue. In fact, blue LED is necessary for the generation of white light, which has opened all the doors of the light source industry to LED technology.

White is obtained by combining red, green and blue light, but white LEDs, in practice, are not made by combining three LEDs. They cover the blue LED with yellow phosphorus and thus manage to emit white light, since yellow is a combination of green and red.

The galio nitride, first, and then the indio-galio nitride, have allowed the white LED to spread everywhere: to the street lighting, to the lighting of houses, to the lighting of cars, to the lighting of boats (the mention of the LED light has spread on the Internet among sailors, for example) and to many other applications. One of the characteristics of the LEDs is its low luminosity. They can be installed virtually anywhere and if they are going to replace a large bulb, it is possible to install many LEDs together. These are the LED bulbs and the light bulbs.

Low consumption

But there is a concern: Amount of light provided by LEDs. In some tests carried out with street lighting, it has been observed that LEDs provide little light compared to that obtained with the use of conventional lamps -- sodium vapor at high pressure. But in this sense, great advances are being made, at present the same luminosity is achieved through the LEDs and also with a low consumption. Conventional lamps provide 85 lumens per watt they consume (the pen is the unit of measure of the luminous flux); current LED lights provide 150 lumens per watt, almost double. This means they have a lower consumption to get the same light.

However, this lighting must be paid. The LEDs are expensive. It is possible that within a few years the LEDs will be reduced much, but it is not known how much they will be marketed. "At this moment you love a street lamp in three or four years," calculates García.

Here too the struggle of researchers is in the world of materials. One of the factors that causes the manufacture of LEDs is the physical base under the semiconductor material (for example, the material that holds the gallium nitride), which is also a semiconductor and should also be transparent in order not to disturb the light that is generated. For example, you cannot use the cheapest semiconductor, since silicon is an opaque material. The base of white LEDs should be sapphire or silicon carbide, both are expensive materials. Common silicon conditioning tests are being carried out and the results indicate that they are on a good path and that the development of this methodology will allow obtaining white LEDs at very low prices. The company Bridgelux ensures that within two years they will begin to manufacture white silicon LEDs.

OLED, flexible light

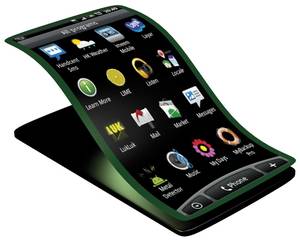

Cheap LEDs are not the only product that manufacturers want to offer. The next generation of this technology is OLED, LEDs based on organic material. In them the semiconductor material is organic, polymers or small organic molecules.

They are very fine LEDs with which flexible displays can be built. If LED technology has revolutionized the light industry, the OLED will further revolutionize, as it is believed. The clothes themselves can become, for example, a source of light or screen; the lighting of a room can be in the curtains. It is the future.

It is the future, although the technology is already developed. But they still have to improve, because they have a big problem: being made of organic matter, DAPs are degraded very quickly. They are expensive and degrade quickly, so technologies through OLEDs (the most common is AMOLED) are not yet very tempting for the buyer.

However, mobile phones with touch screen via OLED are already on the market, for example. Samsung just released one. There is no revolution, but the first products have been launched.

The light has changed thanks to the LEDs and will still change more of the hand of OLEDs. "In Europe, OLED is very fashionable," says García. "People see that there is business there." And, therefore, they grant large grants for the investigation of OLEDs.

And it should be noted that this last revolution comes from organic molecules, the world of carbon. As with electronic graphene, the industry has again resorted to carbon atoms in search of new materials. And it's a very interesting idea considering what was the basis of Edison's first bulb: it used the carbon filament (later those of wolframio expanded). OLEDs will return carbon to the light source industry. The cycle is closing.