3D home door printers

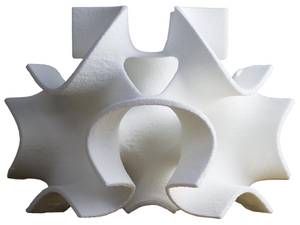

They are called printers because, like traditional paper printers, they regenerate the given model. However, instead of throwing the ink on a paper, they accumulate the material, usually plastic, layer by layer, until they convert the requested model into a three-dimensional object. This is contrary to the traditional way of making the pieces, which normally give shape from a block of materials, removing pieces of material or eroding them in certain places. In addition manufacturing it is part of the vacuum and the material is deposited in places that require the final piece. The interior can have a degree of filling defined by oneself, offering all the possibilities between being completely empty and fully full, modifying the degree of compactness of the pieces.

"The technology of 3D printers has no great mysteries and, in fact, it's not new; these machines have been on the market for 30 years," explains Jon Bengoetxea, director of Tumaker. At the base it is a Cartesian robot that moves in several axes and that is deposited on a head. For this purpose it heats the plastic thread that is rolled in coils or cartridges until it melts and takes out a thin thread. This is what is deposited in layers. "What to do? --adds Bengoetxeak-- what the user has in mind. And the possibilities offered by these tools are infinite."

Bengoetxea recalls a case he would never have imagined to be a customer of them: "There came a waiter asking us if 3D printers could be useful for making molds for their cheese factory. He was very happy because he could do what he had in his head, and he did it to measure."

Creative explosion of socialization

The biggest change that is taking place in relation to 3D printers is that they are "socializing", with a lower cost and a greater ease of use. Therefore, more and more people can be reached, which opens the way to creating more and more uses. "Until now they were used mainly for prototyping in the product design phase," explains Bengoetxea. The prototype allows to create and play quickly and at low cost a replica of the final product and depending on it propose changes in the final product.

3D printers have removed the options from the factories and have taken them to schools, specifically to several Vocational Training schools. This is how Bengoetxea has lived: "In students who are learning to design their products, who until now only saw their design on the computer screen, being able to have in their hands means a change in both perception and attitude: they are immediately aware of what is missing, what needs to be changed, etc. That is, the design process enriches enormously, the students are very motivated".

The companies, with the doors open to creativity, have already started to use 3D printers in their day to day, not only for prototyping, but also for other uses: "They can do almost everything plastic, they are tools, they are protectors, they are components of the final parts... We, for example, manufacture through printers some plastic components for the new printers that we are manufacturing, so that some of them become parents of others," says Bengoetxea. In this way, "the dependency of the suppliers decreases, they make them to measure. In addition, they are guaranteed to be parts without defects and are costly cheap."

Mostly plastic materials

The aforementioned printers and, in general, the ones that are extending most in the market are the 3D that work with polymers. "And to use these printers you have to heat the material and melt and the plastic is excellent," said Bengoetxea. There is a diversity of polymers, of all the existing only a few are used to print and, however, are many. They can be used ABS, PLA, PET, nylon, transparent plastics, flexible plastics, resins with wood dust, plastics that mimic stone, etc.

As for materials, Bengoetxea explained that there is "a lot of work": "The more polymers can be used on printers, the more use printers will have and, therefore, more space will make sense. For example, in the food sector any type of polymer can not be used, so if the printers fit those that can be used, they can be included in this sector. The goal is to minimize limits."

These adaptations have a great dynamic worldwide, and in the company Tumaker also work in homologations. "When a new interesting material comes out, we test it and define how, under what conditions and parameters, the machine must work with this material. Generally it is about adjustments at the software level, for example, the temperature that should be applied to the machine head to melt the material."

Not all will advance

Although 3D printers that are working here and now are those that work with polymers, there are others that work with other materials. Some of them are those that work with metals, that is, machines that print metal parts instead of plastic. One of them was presented at the Machine Tool Biennial held in June in Bilbao. "It's a spectacular breakthrough, being able to make any shape with any metal, but we have to take into account that we talk about technology of another level. These are machines of industrial use with a cost of 500.000 euros. Those in our hands cost between 800 and 1,500 euros," explains Bengoetxea.

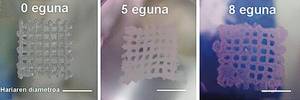

Bengoetxea also sees a great future for 3D printers called bioprinter, which work with cells and are used at research level.

Bengoetxea does not see so clearly the future of 3D printers that have come out for cooking. At the base, in these machines, the plastic wire cartridges are replaced by the components that will contain the food and the separation of each of the components is proceeded with the form indicated by the printer. "As a title they have a lot of strength and the media have given them a lot of echo, but you have to see what future they will have and whether people will support or not. In short, one thing is what can be done with technology and another if it is profitable to do so. And I think the printers that prepare food have a high cost compared to what they offer," he says.

Time will tell which of the technologies that have been created will go ahead and which will not. "You can't foresee where the market will act. At this moment, evolution is dizzying, with few obstacles to creating and doing new things in this field. However, on some occasion there will be a restructuring in which the number of people who work will decrease," announced Bengoetxea.

However, there is no doubt that sooner or later they will become a common tool in households: "At present only technology fans have it, but in view of the speed of penetration in companies, it can ever happen. It is a nice toy, it allows you to do many things and with them you learn a lot".